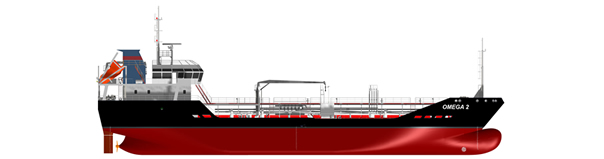

Omega 2 is a sophisticated "Oil Product & Chemical Tanker" designed and built under Bureau Veritas classification, for worldwide trade, to carry petroleum products, liquid chemical products (IMO II type) and to do bunkering services to other ships. During her design made by Istanbul-based consultancy Delta Marine Co., the optimum point of functionality, safety, economy, environmental approach, maintenance and ergonomics has been targeted.

- is a functional ship thanks to her ability to carry petroleum products and more than five hundred (500) chemical products while she can serve as a bunkering ship;

- is a green ship thanks to her low fuel consumption, low exhaust emission levels, double skinned cargo and fuel tanks;

- is an ergonomic ship thanks to less number of cargo tanks when compared with similar ships, her loading & unloading ability both from mid and aft parts, her cargo and machinery automation system controlled from the wheelhouse, her twin rudders, her high maneuvering ability by twin propellers/engines and bow thruster and her wheelhouse giving very wide visibility with lateral sight of 310 degrees and vertical sight by additional ceiling windows;

- is a ship easy to maintain thanks to its design enabling sufficient service spaces for each equipment;

- is a safe ship thanks to its redundant propulsion and maneuvering system.

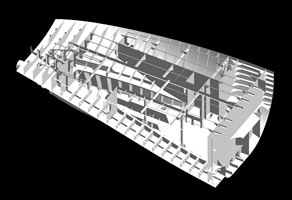

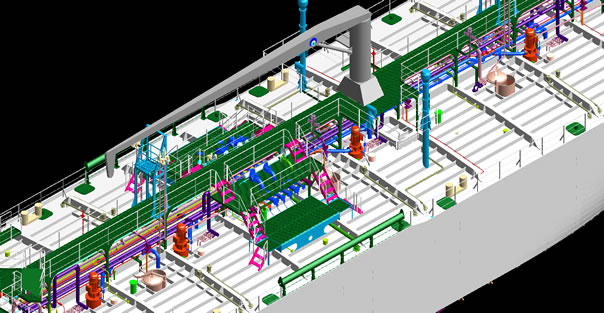

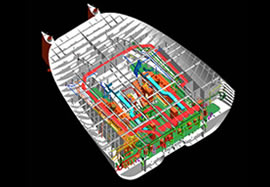

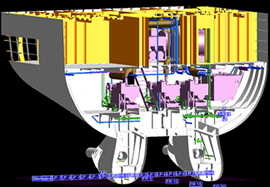

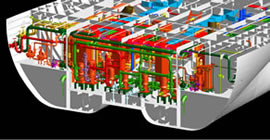

During basic, detailed and production design stages of the ship, state-of-the-art solutions and latest technological tools have been used for naval architecture calculations, advanced engineering applications and production information preparation. Structural strength calculations have been carried out with Finite Element Method (FEM) and the structural properties of the ship is optimized. Hull form design and optimization is realized by using Computational Fluid Dynamics (CFD) tools. For production purpose a 3D hull and outfitting model of the whole ship has been created and production information and documents have been issued.

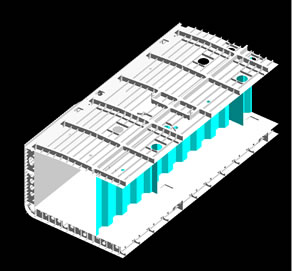

The ship has nine (9) transverse watertight bulkheads one in aft peak part, one in engine room, one in ballast pump room, four in cargo area, one in bow thruster room and one as collision bulkhead. A longitudinal bulkhead divides all cargo tanks on the centerline. Cargo tank bulkheads are of corrugated type and no structural element faces the inner side of these tanks. The construction of aft and fore part is based on transverse system while the basis of the cargo area is construction is longitudinal system. The ship is adequately designed to be an oceangoing ship, sail in iced sea areas up to 60 cm ice thickness and able to stand cargoes having specific gravity up to 1.54 t/m³ while the cargo tanks are fully or partially loaded. Except the ice belt area A-Grade shipbuilding steel plates have been used for construction while for ice belt area the grade has been determined as AH36.

The ship contains eight (8) cargo tanks and one (1) slop tank, which in terms of construction, outfitting and coating are designed in accordance with latest MARPOL and IBC rules to carry petroleum products and IMO II type chemical products. Cargo tanks are painted with phenolic epoxy coating. Cargo piping system together with all other pipes and fittings inside the cargo tanks are made of stainless steel (316L). The cargo system of the ship is designed so that simultaneous loading and unloading of 4+1 different substances in mid manifold area and 2 different substances in aft manifold station can be done without mixture. Total unloading capacity is 600 m³/h (110 mlc, 0.8 t/m³). Steam-heated heating coils are located in each cargo tank. Redundancy of the cargo heating system is achieved by using two lines of coil in each tank. Two steam boilers (one spare) are installed for heating purpose. Each cargo tank is equipped with a pump of 150 m³/h capacity, fixed tank cleaning machine, closed electronic and manual level gauging system and temperature and pressure measurement alarm system. In order to load, carry and unload flammable products and to handle operations of two tanks simultaneously a nitrogen system of sufficient capacity is installed.

The propulsion system of the ship consists of two four-stroke diesel engines and two fixed-pitch propellers. Omega 2 carries Bureau Veritas’ AVM-DPS notation that provides redundancy of the propulsion system enabling the ship continue her course if one of the propulsion systems breaks down. Unmanned engine room control is available thanks to sophisticated automation system and all machinery operations can be carried out from the engine control room located in the engine room. The engine room’s design provides sufficient services spaces for all equipment and therefore ergonomics and safety are provided during operations and maintenance in that area.

Speed, Fuel Consumption and Cruising Range

Design speed of the ship is 12.0 knots and the fuel consumption at this speed is 5.3 t/day. For the same speed value and while the steam boiler is running the cruising range is determined as 3600 nautical miles. With only one engine the ship can sail at 10.0 knots.

Stability

The ship fulfills the requirement of intact and damaged stability criteria in accordance with SOLAS, MARPOL and IBC rules. According to MARPOL damaged stability rules, for all specific gravity values, criteria are met without taking ballast water while in case of IBC damaged stability rules the ballast water should be loaded only for 0.9 t/m³ specific gravity. As a result the CDWT and the DWT values of the ship are the same.

Maneuvering

When sailing at design speed the turning diameter of the ship is 2*Lwl and the stopping distance is 4*Lwl.

To meet the maneuverability requirements during course the ship is equipped with two independent spade type rudder having high leverage coefficient and working at propeller’s wake. These rudders are controlled by two independent ram type steering gears. Steering gears are controlled from the wheelhouse either independently or in synchronization. In case of low sailing speed and approaching/leaving a port or approaching another ship, a bow thruster is installed at fore part to enhance the ship’s maneuvering ability.

The accommodation consists of eleven (11) cabins -two (2) having separate bedroom- all with private lavatory, first aid room, galley, mess room, provision store, laundry, change room and store. Central air conditioning system is installed.

The electrical system of the ship is composed of;

- Three (3) pieces of main diesel generators each of 265 kW capacity and one (1) piece of emergency diesel generator of 99 kW capacity, all producing electricity at 440 V and 60 Hz.

- One (1) main switchboard that enables manual and automatic synchronization of main diesel generators, providing the ability for automatic load share, stand-by and automatic setting in functions and designs for self-redundancy in case of partial damage

- One (1) emergency switchboard that works with emergency diesel generator

- Main and emergency transformers of 220 V all having spares and 24 V DC system.

The wheelhouse is designed with simplicity concept, to increase the control and operational efficiency and to do the duties safely.

For that purpose the areas for cargo operations, machinery operations are determined in the wheelhouse for expedition and control of specific grouped tasks and latest technology and automation techniques are used at maximum possible level.